- Home

- Products

- Air Nippers and Pneumatic Cutting Tool

- Tooling and Fixture

Tooling and Fixture

Product description

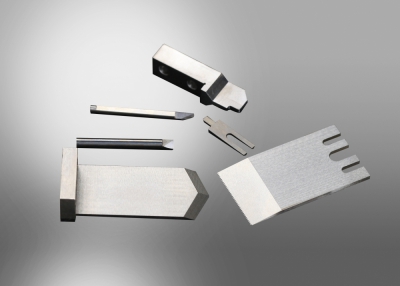

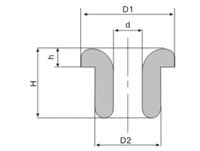

When producing coils, motors, transformers, inductors and other products using an automatic multi-axis winding machine, some tooling and fixtures are frequently used for clamping the chip inductor core, H type inductor core, and the transformer frame. The tooling and fixtures can be divided into an H type inductor chuck, CD chip inductor chuck and transformer tooling and fixture.

Qianhe is equipped with a complete CNC lathe, CNC milling machine, internal and external circular mill, flat grinder and other high precision machining equipment. We are able to independently accomplish heat treatments, polishing and other processes, thus giving us the ability to provide tooling and fixtures in different specifications, shapes, and materials.

Product features

(1) The claw type chuck is embedded with tungsten steel on the tip via a welding process, so that it has a better wear resistance, thus improving the service life.

(2) If the tooling and fixture has a bad concentricity, it will easily cause vibration, which will cause bad wiring of the coil, or even damage the main spindle of the winding machine. A good concentricity requires that precision of each clamping device in a full set of tooling and fixtures can meet the requirements, which is something all Qinhe equipment does, to within a precision of 0.1mm.

(3) We use the designated material of our customers to produce toolings and fixtures. The common materials are S136, SKD11, and EM2 high speed steel. We can also recommend materials according to specific customer applications. For example, if customers require tooling and fixtures with an excellent wear resistance and no corner breaks and cracking, the EM2 high speed steel is an ideal choice.

Production process

Billet production conducted by CNC lathe-punching and tapping accomplished by bench worker-vacuum quenching treatment- WEDM-LS -accurate grinding-assembly and debugging

Hangzhou Qianhe Pricision Machinery Co.,Ltd.

Add.: No.16 Kangzhong Road, Kangqiao Industrial Park, Gongshu District, Hangzhou City, Zhejiang Province, China

Contact number:

+86-571-86179918